Fire proof coatings play a vital role in protecting structures from fire damage. One key factor that affects the performance of these coatings is viscosity. Viscosity refers to the measure of a liquid’s resistance to flow.

In the context of fire-resistant coatings, understanding the impact of viscosity is crucial for ensuring effective fire protection.

Firstly, viscosity affects the ease of application of fire-resistant coatings. Coatings with higher viscosity tend to be thicker and more difficult to spread evenly. This can result in uneven thicknesses throughout the coated surface, leading to potential gaps and weak spots in fire protection.

On the other hand, coatings with lower viscosity are easier to apply and can achieve a more uniform thickness, enhancing the overall fire resistance of the protected area.

Additionally, viscosity influences the drying time and film formation of fire-resistant coatings. Coatings with higher viscosity generally take longer to dry and form a solid film. During this drying process, the coating may be susceptible to damage, such as dust or debris adhering to the wet surface.

In contrast, coatings with lower viscosity dry more quickly and form a solid film with minimal chances of contamination. This ensures better durability and long-term fire protection.

Furthermore, viscosity affects the ability of fire-resistant coatings to penetrate and adhere to various surfaces. Coatings with higher viscosity may struggle to penetrate cracks or uneven surfaces, resulting in inadequate coverage and reduced fire protection.

In contrast, lower viscosity coatings can easily penetrate and adhere to surfaces, ensuring complete coverage and maximizing fire resistance.

Lastly, viscosity impacts the overall performance and effectiveness of fire-resistant coatings. Coatings with an optimal viscosity level can provide better thermal insulation, slow down flame spread, and prevent the release of toxic gases. Conversely, coatings with excessively high viscosity may hinder the coating’s ability to properly react to heat, compromising its fire protection capabilities.

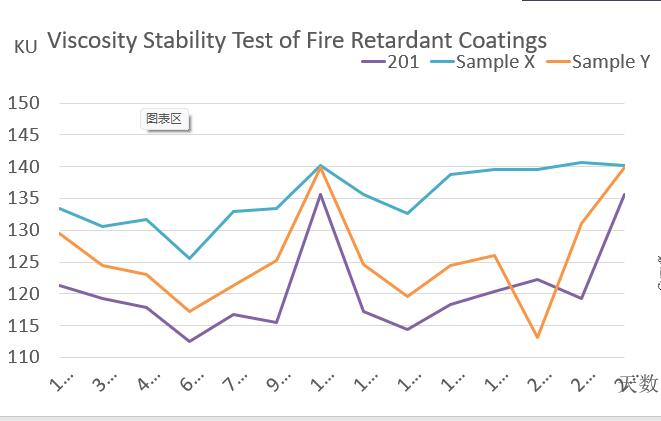

In conclusion, viscosity plays a crucial role in the performance of fire-resistant coatings. It affects the ease of application, drying time, film formation, penetration, and overall effectiveness of the coating. Understanding and controlling the viscosity of fire-resistant coatings is essential for ensuring that structures are adequately protected from fire hazards.

Taifeng Flame retardant TF-201 is APP Phase II with the low viscosity is used for intumescent coating, fire proof coating.

Shifang Taifeng New Flame Retardant Co.,Ltd

Contact: Emma Chen

Email: sales1@taifeng-fr.com

Tel/What’sapp:+86 13518188627

Post time: Nov-02-2023