In the world of plastics, ensuring fire safety is of paramount importance. To assess the flame retardant properties of various plastic materials, the Underwriters Laboratories (UL) developed the UL94 standard. This widely recognized classification system helps determine the flammability characteristics of plastics and enables manufacturers to produce safer products.

UL94 Categories: The UL94 standard categorizes plastic materials into different classifications based on their behavior during a series of fire tests. There are five main classifications: V-0, V-1, V-2, HB, and 5VB.

V-0: Materials that pass the V-0 classification self-extinguish within 10 seconds after removing the ignition source and do not produce flaming or glowing combustion beyond the specimen.

V-1: Materials that pass the V-1 classification self-extinguish within 30 seconds and do not produce flaming or glowing combustion beyond the specimen.

V-2: Materials classified as V-2 self-extinguish within 30 seconds but have limited flaming or glowing combustion after the flame is removed.

HB: Horizontal burn (HB) classification applies to materials that do not meet the requirements for the vertical classifications but do not propagate a flame across the specimen during the test.

5VB: This classification is specifically for very thin materials, typically less than 0.8 mm, which self-extinguish within 60 seconds and do not produce flaming or glowing combustion beyond the specimen.

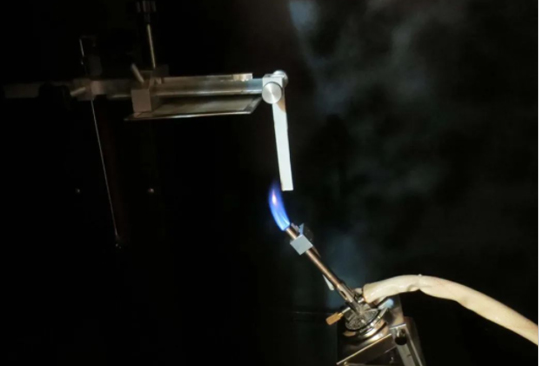

Test Procedures: The UL94 standard employs various test procedures to determine the flame retardant rating of plastics. These tests include the Vertical Burning Test (UL94 VTM-0, VTM-1, and VTM-2), the Horizontal Burning Test (UL94 HB), and the 5V Burning Test (UL94 5VB). Each test assesses the material’s ability to self-extinguish and its propensity for flame propagation.

Material Considerations: When conducting UL94 testing, several factors can influence a material’s flame retardant rating. These include the thickness of the specimen, the presence of external supports, additives, and the specific resin used.

Applications and Benefits: Understanding the UL94 flame retardant ratings helps manufacturers select appropriate plastic materials for various applications where fire safety is paramount. Automotive components, electrical enclosures, consumer electronics, and building materials are examples of industries and products where compliance with UL94 standards is crucial. Utilizing materials with higher UL94 classifications ensures enhanced fire resistance and safety.

Conclusion: The UL94 flame retardant rating system is a vital tool for assessing the fire safety characteristics of plastic materials. By categorizing plastics into different classifications such as V-0, V-1, V-2, HB, and 5VB, the UL94 standard enables manufacturers to understand the materials’ behavior during fire exposure. Compliance with the UL94 standard aids in the production of safer products and ensures that plastics used in various industries meet essential fire safety requirements.

Shifang Taifeng New Flame Retardant Co.,Ltd is a professional halogen-free flame retardant factory in China with 22 years of experience.

TF-241 is blend APP flame retardant which can be used for PP/HDPE. The FR materials can reach UL94 V0.

Contact: Emma Chen

Email: sales1@taifeng-fr.com

Tel/What’sapp:+86 13518188627

Post time: Oct-24-2023